22 Mar

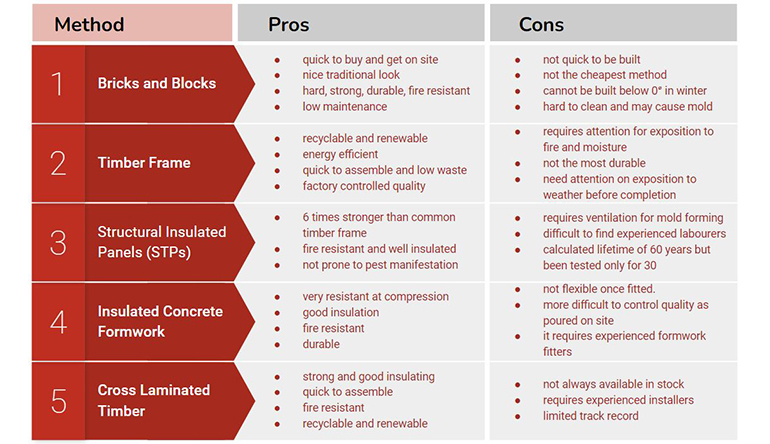

Of course the budget and the overall design are affected by which construction method is used. The construction method may also affect your builder choice, as each builder may have experience using one method in comparison to another. Let’s see now a bit more in detail the 5 more used construction methods in UK, and then pros and cons of each of these more in detail. Not forgetting that there are also other construction methods that can be used and might be more convenient for your projects, like for example prefabricated concrete panels with insulation, just to name one not listed below.

Bricks and blocks Timber Frame Structural Insulated Panels Insulated Concrete Formwork Cross Laminated Timber

Bricks are probably the oldest of the construction methods since first cities were born in Mesopotamia! They come in standard measures and different colors depending on the cooking temperature. They give texture aesthetically and are very commonly used for constructions in UK.

Most commonly the colored bricks are used on the outer skin, the visible one, while blocks are used on the inside skin, and in the middle is located the insulation, as well as few connectors in steel to make the composition more solid.

These are usually easy to order and quick to get on site, but the construction process is the slowest compared to all other methods below, which of course makes the labour costs raise up.

Timber frame construction uses timber studs and rails, together with a structural sheathing board, to form a structural frame that transmits all vertical and horizontal loads to the foundations. Platform frame is the most commonly used method in the UK. Each storey is framed with floor-to-ceiling height panels and the floor deck of one floor becomes the erection platform of the next.

Usually the all structure is ordered in one go, and weeks later is quickly assembled on site, usually from the same fabricators that created it.

This is also a largely used method for construction however is more subject to weather conditions than bricks during the assembling of the whole house. It can lose in fact structural resistance and even get bad if exposed to moisture.

Structural Insulated Panels are rigid panels of foam or polystyrene insulation, that have been sandwiched between Oriented Strand Board (OSB). They come as prefabricated boards, which can simply be slotted together, to create the entire structure of your new home. They can be used for both walls and floors and are very good from insulation perspective (both thermal and acoustic).

They have been used across the US for around 30-40 years, but have only become popular in the UK in the last 10 years, as the need for well insulated homes has become more apparent. They are usually clad on the outside of the home with brick or sometimes rendered, to ensure that the insulation remain entirely dry.

Concrete can be poured in a lot of different assembled formworks, the most common of which is made of wood, and these formworks will define the final shape. This method is very commonly used since more than a century in its modern history and so finding experienced builders that can deal with concrete is usually not an issue. Concrete in fact in his simplest method is used largely for structures. However In Germany during the 70’s this system has been innovated for perimeter walls adding insulation directly in the formwork before pouring the liquid concrete.

This system does not require a lot of maintenance and it can resist even to floods but unfortunately once the external perimeter is built with this method, changes to the design become very expensive and difficult to realize, Plus experienced builders with this kind of expensive formwork are rare, being the innovation quite recent.

CLT is made by finger jointing kiln-dried dimensional lumber to the required size and gluing it together in perpendicular layers. The layering is repeated to the desired thickness, typically three, five, or seven layers. These solid panels are then compressed and set to dry. What results is a product that is strong and stable and overcomes the inconsistencies inherent in unmodified wood.

The elements are set in place as structural load resisting systems, or for select elements such as floors, walls, or roofs, leaving very little waste.

This construction method is very quick to be assembled on site, but very often it takes time to get there if stock is not ready from material suppliers. Its usage raised a lot in recent times in all developed countries and not only because it’s environment friendly but also because of its structural qualities. It comes also in different colors depending on the hardwood used.

Leave a Comment